ARC Engineering Industries

Your search for a concrete mixer machine ends here!

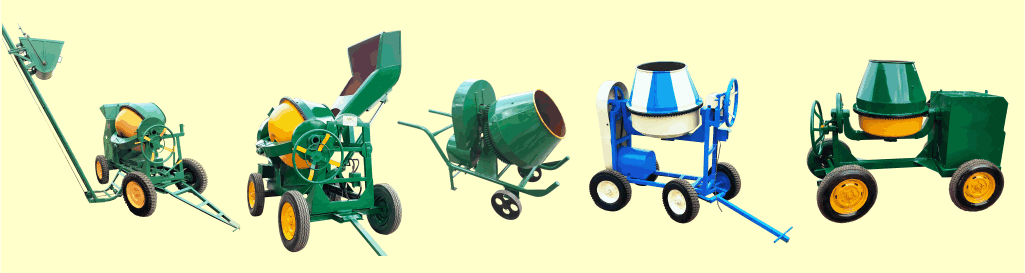

We ARC manufacturing various types of concrete mixer machines as per the construction industry needs. Concrete mixer machines play a significant role in building construction for mixing cement, jally, crawl, and sand. Even though Readymix concrete plays an important role nowadays, we must need at least one type of concrete mixer for minor building works on-site. These machines are the most trusted and promising raw materials like cement and mixing quality. So without further ado, let’s dive into our types of machines and their uses and specification.

Mini Concrete Mixer machine

Concrete mini mixers are primarily used in small concrete buildings and cement wall plastering works. These machines run on a single-phase electric supply, are easily movable, and can lift to the floors. ARC engineering industries manufacture unique types of concrete mini mixers that are shown below.

Concrete mini mixer

This machine is also known as the Hand mixer machine and Baby concrete mixer machine.

It has been over a year since its launch, yet this type continues to be one of the most popular among Builders and engineers. Even today, you can find people looking out to buy these machines.

Made of heavy Mild steel sheets and castiron drums make, the machine is long-lasting. Also had the option to rotate the drum using a handle during a power failure situation.

To know more and the specification, click here.

Tilting Drum Concrete mini mixer

The tilting drum concrete mixer machine is a particular mini mixer machine launched by arc engineering industries for Small concrete buildings and cement mixing in wall plastering. Easy handling, able to get mixed concrete in a wheelbarrow. Electrical single phase, portable and heavy type.

Our machine is made from a heavy mild steel sheet compared to the Chinese tilting mixer available in the Indian market. Tilting in mixed load is easier in geared steering. Four wheel tire helps in easy transferable on construction sites.

To know more and the specification, click here.

Without Hopper Concrete mixer machine

Without Hopper Concrete mixer machines are basic mixers used in construction industries. in this machine, you have to feed cement and sand and crawl directly into the drum like a mini mixer machine. But the machine was made from a heavy cast iron drum and mild steel cone.

This machine is available in 7/5 Cft (3/4 cement bag mixing capacity) and 10/7 Cft (1 cement bag mixing capacity)

One Bag Concrete Mixer Machine

ARC One bag concrete mixer machine is powered by a 6 HP air-cooled diesel engine or 3 phase 5 Hp electrical induction motor, with a 10/7 Cu. Ft (1 Bag Cement ) mixing capacity and with ambassador tyre wheel.

To know more and the specification, click here.

7/5 Cft (3/4 Bag) Concrete Mixer Machine

ARC three-quarters bag concrete mixer machine primarily used in home construction, and concrete roof works in hill stations, powered by a 6 HP air-cooled diesel engine or 3 phase 3 Hp electrical induction motor, with a 7/5 Cu. Ft (3/4 Bag Cement ) mixing capacity and with ambassador tyre wheel.

To know more and the specification, click here.

Self-loading concrete hopper mixer machine

Self-loading concrete types mixer are attached loading hopper for feeding sand, cement, crawl before loading into the drum. These machines are used mainly by contractors and builders in commercial, industrial, apartment buildings, and Roof concrete builders. With the help[ of a loading hopper, it’s easy to measure the quantity of material used for concrete.

Hydraulic Loading Hopper Concrete Mixer Machine

The hydraulic self-loading Concrete mixer machine has a hydraulic power loading hopper, 6Hp air-cooled diesel engine or 5 HP 3 phase induction motor, and ambassador tyre wheel.

To know more and the specification, click here.

Rope Clutch Loading Hopper Concrete Mixer Machine

The mechanical clutch self-loading Concrete mixer machine has a rope for loading hopper, 6Hp air-cooled diesel engine or 5 HP 3 phase induction motor, and ambassador tyre wheel.

To know more and the specification, click here.

Concrete mixer machine with lift

Before, ARC Engineering Industries introduced an attached Concrete mixer with an attached ladder lift. We used separate machines for roof concrete, one for concrete mixing and another for lifting, which makes transporting two machines to customer sites. So we found a solution is attached Concrete mixer. That makes roof concrete cost-effective by reducing expenses in Diesel (fuel), Manpower (machine operator), transport, etc., and customers can use the Concrete mixers separately when needed.

1 Bag Concrete Mixer with attached Ladder Lift

This type of concrete mixer machine is used for Roof concrete works for homes and small buildings. In south India, slab concrete builders and contractors use ladder lifts for concrete roof building up to 55 feet.

It was powered by a 10 HP Kirloskar air-cooled engine, mechanical clutch rope lift system and jeep tyre wheel.

Available in two types as per capacity requirement

- 1 Bag capacity (10/7 Cft)

- 1/4 Bag capacity (7/5 Cft)

To know more and the specification, click here.

Concrete Mixer with Ladder Lift and Hopper

This type of concrete mixer machine is used for Roof concrete works for homes and small buildings. In south India, slab concrete builders and contractors use ladder lifts for concrete roof building up to 55 feet.

It was powered by a 10 HP Kirloskar air-cooled engine, mechanical clutch rope lift system and jeep tyre wheel.

Available in two types as per capacity requirement

- 1 Bag capacity (10/7 Cft)

- 1/4 Bag capacity (7/5 Cft)

To know more and the specification, click here.

Bed type concrete mixer for brick industries

These types of concrete mixer machines are commonly used in brick industries for manufacturing Solid block bricks and hollow bricks. These machines are fixed and need a substantial bed to set, and Electrical motors power them. ARC engineering industries manufacture two types of bed-type mixer machines. One with standard steering and another one with hydraulic power steering

Bed-type Cocnrete mixer

Without hopper bed-type, concrete mixer machines are the perfect fit for small startups, small scare brick, and concrete mould industries. It comes with a 3 phase induction motor, cast iron drum, and 6 mm cone top. Available in two types as per capacity requirement

- 1 Bag capacity (10/7 Cft)

- 1/4 Bag capacity (7/5 Cft)

To know more and the specification, click here.

Bed-type Cocnrete mixer with Hydraulic Loading Hopper

These hopper bed-type concrete mixer machines are perfect for large-scale industries manufacturing brick, cement pipes, readymade concrete walls and concrete mould industries. It has a 3-phase 5HP induction motor, cast iron drum, and 6 mm cone top and hydraulic motor power hopper for self-loading unmixed cement, sand, crushed stones etc.; available in only one per capacity

- 1 Bag capacity (10/7 Cft)

To know more and the specification, click here.

Pan mixer

ARC pan concrete mixers are vertical shaft concrete mixers stirred by the ring gear driving, reversing the raw material to mix wet and dry cement concrete. It is a concrete mixer for the fly ash brick industry, medium-sized precast plants, and other projects. It has the advantages of smooth operation, low energy consumption, compact structure, intense light, high production efficiency, mixed plasticity, dry stiff, mobility and lightweight aggregate concrete and mortar. This machine is available in two types are

1. Pan mixer – manual feed.

2. Pan mixer with hydraulic self-loading hopper

Pan mixer

ARC Engineering Industries is a Manufacturer of Pan Mixer in Coimbatore, and we Also Undertake Customised Design. Pan mixer powered by 5 HP electrical motor.

Concrete mixer machine sale in coimbatore, tamilnadu.

What is the best type of concrete mixer?

That is all about your requirement and industry like some need a concrete truck, fixed one, or Portable.

What is concrete mixer used for

Concrete mixer machines are used in the building construction industry to mix cement, crushed stone, and sand for perfect concrete building results.

What is the cost of a concrete mixer?

Concrete mixer machine price varies as per you selected model and requirement ARC engineering industries always pleased to give you best quote in mate kindly contact us (+91 9092211778)

What is the standard size of concrete mixer ?

Usually, the concrete mixer machine size is below 11 ft long and 6 ft wide. ARC manufacture concrete mixer to fit in the small-size truck.

Where is ARC concrete mixer company located?

We are located in Coimbatore, Tamil Nadu, and we have branches in Chennai, Erode, Guntur, and Odissa.